Warped Rotor Diagnosis Needs Further Investigation

Often when a customer has a problem with brake pedal pulsation, it is misdiagnosed as a warped rotor. However, rotors don’t permanently warp but they can wear out unevenly due to disc thickness variation caused by lateral runout. Learn how lateral runout and disc thickness variation can cause brake pedal pulsation.

What is Lateral Runout?

Lateral runout is the side-to-side movement of the rotor while it is rotating. Most vehicles have extremely tight lateral runout specifications of two thousandths of an inch or less. If the lateral runout exceeds the manufacturer’s specifications it can lead to disc thickness variation.

How Does Lateral Runout Contribute to Disc Thickness Variation?

If the runout becomes severe, the rotor will wobble side-to-side. While the rotor is wobbling, the brake pad contacts it on each rotation, either on the frontside or backside of the rotor. If the brake system has a semi-metallic brake pad, the rotor hitting the pad will wear spots into the rotor, taking bits of material off the rotor to make it thinner. With a ceramic brake pad, the contact will transfer brake pad material onto the rotor, causing the rotor to become thicker. The contact causes the rotor to be thicker or thinner in some spots; a condition known as disc thickness variation.

As the part of the rotor affected by disc thickness variation runs through the caliper while the brake pad is applied, it causes fluid displacement which pushes the pistons out. The change of the brake fluid rising or falling during braking causes the pedal to pulsate.

How to Measure Lateral Runout

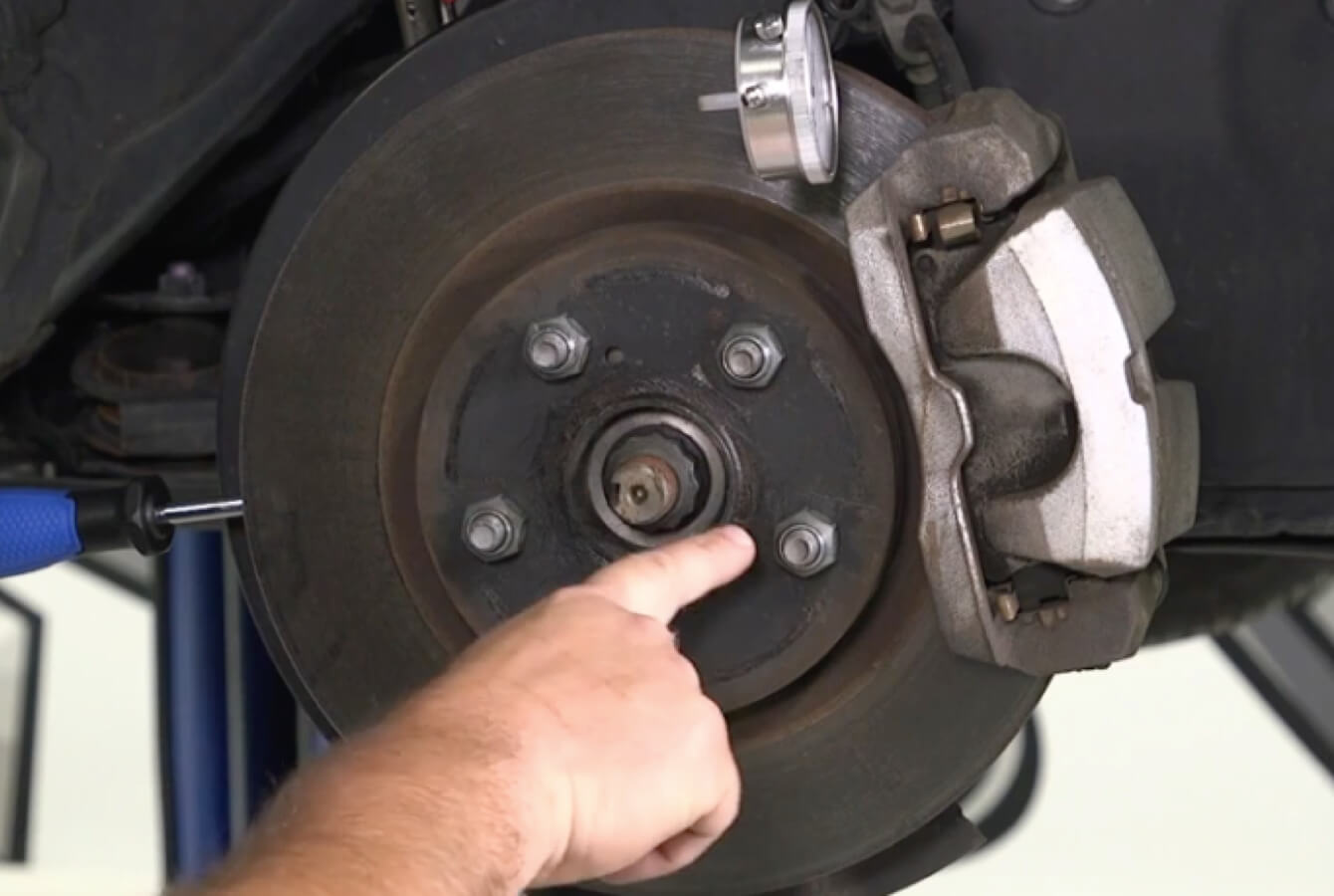

Using a vise-grip style dial indicator, it is easy to measure lateral runout. Get started with the proper set up:

- Attach the indicator to a solid mounting point

- Have the dial indicator positioned about 1/2" from the outside of the rotor

- Ensure that all lug nuts are tightened down evenly

What Causes Lateral Runout?

Many times, the cause of lateral runout is a stacked tolerance problem. The rotor mounts to the hub and if the hub has been on the vehicle for a long period of time, it can have a buildup if rust. Even a small piece of rust on the mating surface of the hub and the rotor can cause lateral runout.

How to Avoid Lateral Runout?

When replacing a rotor, it is imperative that the hub surface is free of rust before installing the new part. Use a hub cleaning disc holder that slides over the studs to clean the area around the studs and then use a cleaning disc to clear away the rest of the rust.

Once you have installed the new rotor, be sure to measure the lateral runout to ensure that it is within manufacturer specifications.

Learn more about quality brake pads and rotors, find your car part, or find where to buy your auto part today.

The content in this article is for informational purposes only. You should consult with a certified technician or mechanic if you have questions relating to any of the topics covered herein. Tenneco will not be liable for any loss or damage caused by your reliance on any content.

OTHER PARTS FOR YOUR VEHICLE

Wagner® offers a wide variety of products for all of your automotive needs. Check them out today!